Medical implant surgery, by its nature, already involves customisation to fit the specific anatomy of patients. As skilled surgeons, you are already using a degree of ‘customisation’ as you select sizes, sculpt, and alter the prostheses you work with to achieve the best fit possible for a standard implant.

The question is, how precise, successful, and economical are your current methods, and could they be enhanced further?

For example, during hip replacement, the femoral piece and socket align closely with the patient’s anatomy. However, it’s the surgeon who makes the patient’s host bone fit an ‘off-the-shelf’ implant.

Unfortunately, in some cases, on-the-spot alterations result in minor bone and soft tissue inconsistencies or misalignment. These limitations can lead to discomfort and the requirement for corrective surgery. On-the-spot alterations also add additional pressure to the operating theatre’s already high-pressure environment, extra theatre time and longer recovery.

Healthcare providers recognise that older adults, such as those most likely to be undergoing a joint replacement, suffer more significant side effects due to lengthy procedures under general anaesthetic.

When comparing generic implants versus fine-tuned, original designs, why are the long-term results so compelling?

Perhaps you haven’t considered designing and printing custom implants to be a practical option yet.

At Trecco, we believe personalised healthcare is leading the way for practical and profound reasons. Is it time for you to move in this direction as well?

In this article, we’ll highlight advances in this exciting field and discuss the benefits versus drawbacks you may encounter when selecting custom implants over lower-end generic options.

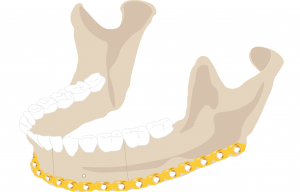

What is meant by Patient-Specific Implants, and how could they impact your practice?

Patient-specific implants (PSIs) might be considered the bespoke tailoring of the surgical implant industry. Until now, surgeons may have thought completely

personalised PSI detailing was a “nice to have,” but not necessary or affordable.

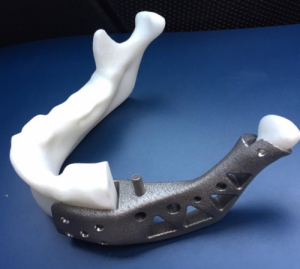

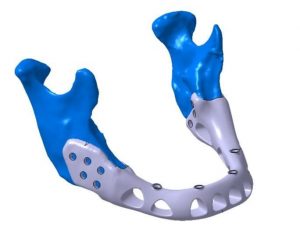

Custom 3D printed implants, and surgical guides represent much more than a higher-end, quality design and fit. Not only are they more economical than ever, but the value is also far from superficial and can make a lasting impact on patients’ lives. Virtual surgical planning (VSP) based on medical imaging and direct surgeon input means these devices not only fit but perform exactly as you want. That’s incredibly satisfying and efficient. Imagine on-the-spot adjustments in the OR and unforeseen postoperative issues like malposition, friction and sheer removed from the equation.

What custom implants represent is a whole new level of reassurance for the surgeon and patient alike.

What do bespoke suits and luxury cars have to do with PSIs?

Even when we instinctively know custom is desirable, fiscal instincts may tell us to choose cheaper, off-the-shelf faster options. Economics is often a driving factor in medical treatment due to funding structures and budget silos. This situation usually means that the implant’s price drives the decision rather than the actual cost of the procedure and postoperative recovery to the healthcare provider.

However, the superior performance and lasting quality of a PSI is commercially comparable to traditional methods when viewed in overall terms.

Consider bespoke clothing hand-crafted for individual clients. The investment in made-for-you pieces ensures a flawless fit, with no detail overlooked. A garment designed and tailored for you will last and hold its quality fit and feel for years to come. Likewise, most people don’t purchase a luxury car without selecting personalised details to fit their needs. A high-end item you’ll enjoy every day should have the style, materials and performance that make each journey a pleasure.

When it comes to your prized possessions, personalisation pays off; how much more is this true for personalised medical implant materials fused with someone’s tissue, harmonised with their body, and held to high performance demands every day?

In medicine, custom quality is lived – all day – every day.

Off-the-shelf seems easier but has drawbacks

Are you currently using out-of-the-box, standardised implants for maxillofacial and orthopaedic surgery?

Industry-standard implants are sufficient for some reconstructive cases, but surgeons often face incredibly complex challenges treating degenerative defects, craniofacial trauma, tumours in the bone and high-wear implant zones.

Standardised implants deliver unpredictable results under the demands of movement and function over time. No two patients are genetically matched, so variances in fit are inevitable drawbacks of generic implants.

Additional complications faced using standard implant approaches include:

• Poor stability• Bone deterioration

• Additional surgeries and costs

• Pain and lower quality of life

• More serious postoperative side-effects

Historically, planning for challenging surgical cases required the surgeon’s interpretation of two-dimensional imaging data such as x-rays. With the entire 3rd dimension missing from the equation, blind spots inevitably lead to inaccuracies. Of course, spontaneous adjustments, excellent instincts and experience make the best of these circumstances; however, surgeons and healthcare professionals need not be constrained by the methods of the past today. Solving complex trauma anatomical defects can be achieved through advanced planning, modelling, and technically superior design solutions. Utilising anything less than custom, the first-time, may cause unnecessary suffering and ill health for your patients.

Does Custom Cost More?

Costs have been higher for superior design and manufacturing solutions, historically. However, technological advances accelerate due to competition, and market accessibility continually improves. According to the (Tack et al., 2021) study, the average cost of revision hip arthroplasty in Belgium is €15300 wherein all cases patient specific implant shows to be more cost effective than Custom Three-flanged Acetabular Components with an average cost reduction of €1266. Also (Binhammer et al., 2020) reported more cost effectiveness off titanium PSI for large paranasal sinus defects and large ablative “unknown” cranial defects.

As a result of using PSI, revision costs have decreased, and the positive long-term benefits are steering discerning surgeons in this direction. When considering reduced revisions and reduced operating theatre time, the overall costs for PSIs are falling more in line with traditional methods and will continue to improve.

The value of customisation compared with off-the-shelf is compelling.

• A tailored result – leading to reduced theatre time and cost.

• Preservation of healthy biological tissue – faster recovery and reduced post-op care.

• The ability to plan and achieve perfect symmetry efficiently in theatre.

• An exact fit prolongs the implant life – minimising revisional surgery.

• Custom-fitted implants perform predictably, resisting wear or sheer and withstanding weight.

• Better patient outcomes, improved recovery and reduced pain remove additional healthcare costs.

If you are a surgeon, you know any operation hinges’ success on tight margins for error.

Less time required to complete procedures, accurate, reliable fit, and fewer risks makes the process and result better; this is what PSIs can deliver.

Additional benefits for customisation of medical implants include:

• Minimised need for bone removal.

• Controlled surgical bone removal.

• Optimised screw trajectories.

• Develop 3D-printable materials for education and planning.

• Decrease implant volume and use lattice structures for reduced weight and improved osseointegration without compromising strength.

Limitations of Older Surgical Techniques

• Orthopaedic implants replace missing joints or bones and support damaged bone. The role they play demands incredible strength from high-performance, lightweight biocompatible materials.

• An ill-fitting implant places uneven loads on the surrounding bone and will not perform as intended. Some healthy bone may even be lost in the process.

• Standard implants are available in various stock sizes but require alteration in the operating theatre due to imprecise fit. This consumes costly operating-theatre time for reshaping implants or grinding the patient’s bone to match. Freehand methods can involve estimates, trial and error, and several adjustments.

• Budgetary concerns are always relevant, and hospitals required to stock numerous implant sizes and variations incur a high but often hidden cost for inventories.

• Whenever a revision, replacement or repair occurs, wear, tissue damage and infection risks are reintroduced, placing the patient at unnecessary additional risk.

• Standard treatment for bone defect repair requires taking bone from other sites or fillers to augment an implant’s fit, causing further trauma. The longer surgery times necessary for these complicated cases elevate anaesthetic risks, infections, and other complication concerns.

• Lengthy hospitalisation and related healthcare costs can be seriously detrimental to a patient’s well-being and outcome.

The new generation of custom, 3D printed medical implants can address or prevent many of these concerns. Let’s take a closer look at the benefits of personalised implants.

Virtual modelling, means planning with clarity

• Virtual 3D planning and implant design are enabled with computer tomography (CT scans) and digital modelling.

• Computer models gauge material performance and resilience in all scenarios to clear up unknowns for long term success.

• Additionally, 3D printed models allow interactive, precise visualisation and unmatched planning capabilities for surgeons. In some cases, the surgical team can rehearse the entire procedure before the actual case, significantly reducing expensive theatre time.

• A surgeon showing patients a model to describe procedures versus MRI scans helps improve clarity and peace of mind.

A unique benefit of working with Trecco is that surgeons can speak with product engineers and have an integral hand in the design process. They supply the necessary imaging and explanations to create precision solutions. You will approve all designs before manufacturing, then receive devices that work as precisely intended.

Do VSP and 3D implant printing represent a paradigm shift for surgeons and patients?

A winning protocol on the leading-edge of surgery is the combination of surgical guides and PSIs custom-designed for individual cases.

The Trecco team are pioneers. We offer you a portfolio of personalised implants, guides, and successful case studies representing the best additive manufacturing and 3D printing medicine has to offer.

Areas we focus on improving include time restrictions and costs, as we continually strive to reduce both for greater accessibility.

Our medical engineers and materials specialists work in a close-knit team with low overhead compared to extensive facilities. You can access highly advanced manufacturing with a hands-on, friendly approach.

Personalised, precision medicine is not only on the horizon. We’re already helping surgeons see the difference it makes in practice now.

Find out more about working with Trecco by contacting info@trecco.co.uk.