Trecco designs and manufactures patient-specific implants and surgical guides. Each case is developed individually from the patient’s imaging and the planned procedure, with design proposals reviewed before manufacture.

Our engineering background informs how we manage design control and manufacturing discipline, while keeping the focus on practical clinical use. This work is most commonly applied in

.

.

.

Our work falls into two areas: patient-specific implants and surgical guides.

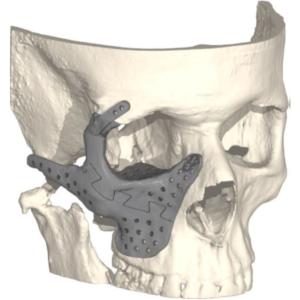

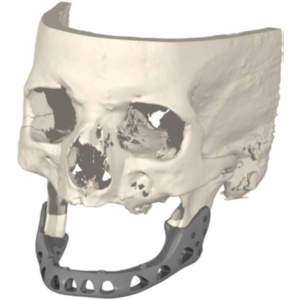

Both are developed from three-dimensional models of the patient’s anatomy and the planned reconstruction. They are used to support cranio-maxillofacial procedures where anatomy, access, or prior surgery make standard solutions unsuitable. Customisation allows the design to reflect the individual anatomy involved, with the emphasis on predictable fit and practical use in surgery.

Once a design is agreed, manufacture proceeds for surgery, with shorter lead times available when clinical urgency requires it.

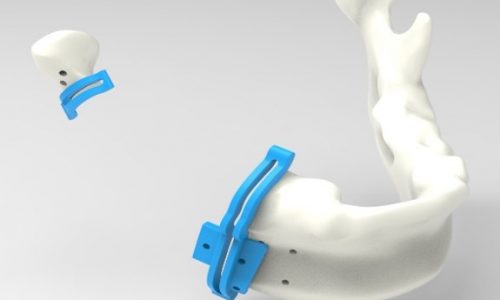

The aim is to reduce uncertainty around fit and placement while keeping the surgical workflow clear and predictable.

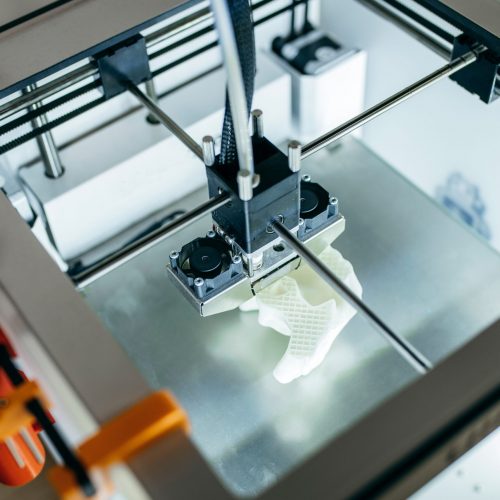

Patient specific implants and surgical guides are developed from the patient’s CT or MRI data and the planned procedure. Three-dimensional models are used to review anatomy and constraints before design is finalised. Design proposals are shared for review prior to manufacture, allowing the implant or guide to reflect the specific clinical requirements of the case.

Patient-specific implants are designed to reflect an individual patient’s anatomy and the planned reconstruction. Many are used to replace missing bone following trauma, resection, or tumour removal, where standard implants are not suitable.

Patient-specific surgical guides are 3D-printed tools used to transfer preoperative planning into surgery. They are designed to help position instruments and guide bone cutting in line with the agreed plan. Each guide is developed during preoperative planning and reviewed with the surgeon before manufacture.

In cases where the required material is not suitable for additive manufacturing, design work can be carried out in CAD and translated into mould-based fabrication.

This allows patient-specific geometry to be developed even when 3D printing is not the final manufacturing route.

If you’d like to discuss whether this approach is appropriate for a particular case, please get in touch.

Typical applications include surgical cut guides, specialist instruments, and patient-specific prosthetic components.

WhatsApp us